VIP Prefab - Building More Efficiently!

Over the last few years our customers have been looking for faster and more advanced solution to the commercial and residential build process enabling a quicker and superior product to the end user.

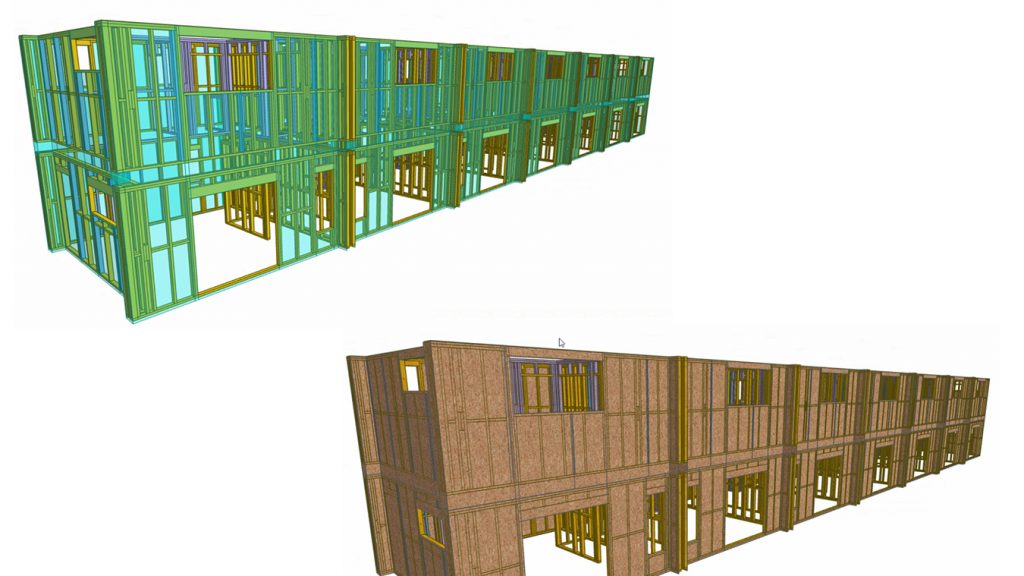

A simple solution that the market was struggling to provide was an effective way to supply prefabricated build systems such as sub-floors, mid-floors, wall panels and roof cassettes.

Working closely with builders and their needs VIP have produced an offer that has considerably reduced the time and manual labour on site requiring only simple fixing rather than traditional time-consuming build processes.

Having completed more than 500 panels in the past 18 months and with a factory shift capacity of 1200lm VIP are well equipped to manufacture anything from a small garage to large commercial projects in short turnaround times.

Mid Floors

Truss Cassettes

Pre-Fabricated Pods

Prefabrication With Project Velocity & Kainga Ora NZ

Our prefab team achieved a first by installing our pod system straight onto the piles, with all manufacturing of the multi-level homes completed offsite at our dedicated prefab facility. Within 4 hours of the initial lift, our prefab system was completely installed, allowing for roof installations within the week!

VIP Frames & Trusses is proud to be working with Project Velocity, and Kainga Ora to speed up home construction in New Zealand. We are proud to be aligned with the velocity strategy, vision and collaboration with key stakeholders to deliver high quality pre-fabricated homes.

POD Systems, Mid Floors & Roof Cassettes For Mike Greer Commercial

We’ve been developing our prefabrication systems for the New Zealand building industry and our latest offering is our “POD System”

This video demonstrates the speed and efficiency utilising our frames on the first floor, a combination of full pods, mid floors and roof cassettes!

13 X 2 Storey units were completed across two nights on site, a tremendous effort by the builders on site and the Mike Greer Commercial team!

Our prefabrication innovation really is the solution to building larger developments much more effectively and efficiently!

91 Unit Development on Brougham St, Christchurch

91 pre-fabricated units built offsite at our Christchurch factory, stored in our yard and then transported to site using our own trucks!

Watch our video to see how the prefabrication process has saved build-time, improved site safety, increased site efficiencies and will have quality social housing built faster for those families in need

Wanaka Pre-fab Delivery & Install Case Study

Delivery included Prefabricated midfloors, frames and trusses for 8 units! Our trucks arrived on site Friday morning, unloaded all 8 pre-fabricated midfloors into place. We then unloaded the timber frames on the same day so they could be stood over the weekend and have our trusses fully erected by Monday afternoon!

Prefabricated Mid Floors With Structural Steel Installed

Watch as Steven Meates from Dyers Road ITM explains the install process of the VIP Frames & Trusses prefabricated mid floors on this Central City Christchurch development for Consortium Construction Ltd.

A new challenge for the team on this project was installing the VIP Structural Steel into the mid floors before they got to site, once the mid floors were lifted into place the steel lined up perfectly with the steel columns that were already installed, these then create the structural portals in each unit.

The mid floor install onsite was completed in approximately 6 hours and the first floor frames were then lifted into place on the same day ready for the builders to complete framing on the first floor.

An outstanding and efficient job by all the team involved!

Mid Floor Install - Willams Corp, Waltham Christchurch

Time-lapse video of Mid Floor Installation in Waltham Christchurch on a multi-unit development 2020!

Mid-floors Completed In 3 Hours!!

Watch the process from start to finish on this job completed in Christchurch Central City. This job was completed in 3 hours once on site and has saved the client approximately 3 weeks.